The Ultimate Guide to Concrete in Modern Construction: Techniques, Types, and Best Practices

Introduction: Concrete:- The Foundation of Modern Construction

Concrete is more than just a building material; it is the backbone of modern construction. From towering skyscrapers and expansive bridges to residential homes and roadways, concrete’s versatility, strength, and cost-effectiveness have made it indispensable. Despite its ubiquity, many construction professionals underestimate the complexity involved in producing high-quality, durable concrete. Success depends not only on ingredients but also on proper mix design, curing, reinforcement, and modern management practices.

In this article, we will explore everything construction professionals need to know about concrete. By understanding its types, properties, techniques, and innovations, you can ensure that your projects are not only structurally sound but also sustainable, efficient, and future-ready.

Understanding Concrete and Its Types

Concrete is essentially a composite material composed of cement, water, fine aggregates like sand, and coarse aggregates such as gravel. However, its performance varies depending on the type, mix proportions, and intended application.

Normal Strength Concrete

Normal strength concrete is the standard form used in most everyday construction projects. Typically achieving compressive strengths up to 6,000 psi, this type is suitable for residential buildings, pavements, footings, and slabs. Its workability and durability make it a dependable choice for general construction where special structural properties are not required.

High-Strength Concrete

High-strength concrete (HSC) is engineered to exceed 6,000 psi in compressive strength, making it ideal for demanding applications like high-rise buildings, heavy-duty pavements, and bridges. Achieving such strength requires careful selection of materials, low water-cement ratios, and sometimes special admixtures that enhance both workability and long-term durability.

Lightweight Concrete

Lightweight concrete incorporates lightweight aggregates, reducing its overall density while retaining structural integrity. This material is particularly advantageous for roof decks, precast panels, and insulated floors, where reducing load is critical. Its thermal insulation properties also make it energy-efficient.

Self-Compacting Concrete

Self-compacting concrete (SCC) flows into place under its own weight, eliminating the need for mechanical vibration. SCC is a game-changer for projects with complex formworks or dense reinforcement. By ensuring uniform compaction, SCC minimizes defects like voids or honeycombing, which can compromise structural integrity.

Reinforced Concrete

Concrete excels under compression but is weak under tension. Reinforced concrete solves this problem by combining concrete with steel reinforcement, typically in the form of rebar or mesh. It is used extensively in beams, columns, slabs, retaining walls, and foundations. The synergy between steel and concrete allows structures to withstand both compressive and tensile forces, providing enhanced stability and durability.

Pre-stressed Concrete

Pre-stressed concrete introduces compressive forces into structural elements before they are subjected to external loads. This technique enhances load-bearing capacity and reduces material requirements. It is widely used in long-span bridges, industrial floors, and roof structures.

Decorative and Specialty Concrete

Beyond structural uses, concrete can also be tailored for aesthetic or specialized purposes. Stamped or colored concrete, polymer-modified concrete, and fiber-reinforced variants allow architects and builders to combine beauty with durability. Specialty concrete finds applications in public spaces, pavements, and interior designs, offering both function and visual appeal.

The Art and Science of Concrete Mix Design

Achieving the perfect concrete mix is both a science and an art. The mix must balance strength, durability, workability, and cost. The main ingredients—cement, aggregates, water, and admixtures—must be combined in precise proportions.

The first step in mix design is defining project requirements, such as target compressive strength, exposure conditions, and durability considerations. Next, materials are selected based on quality, availability, and compatibility. Using standardized methods like ACI or IS codes, engineers determine mix proportions and conduct trial mixes to verify performance. Adjustments are often necessary based on site conditions or test results to ensure consistency and optimal performance.

Admixtures play a crucial role in enhancing concrete properties. Plasticizers improve workability without increasing water content. Retarders and accelerators adjust setting times in response to temperature variations. Air-entraining agents enhance resistance to freeze-thaw cycles, while fiber additives increase tensile strength and reduce cracking. Understanding how each component interacts is critical for producing concrete that meets structural and environmental demands.

Curing Concrete: Unlocking Its True Potential

Curing is a vital yet often overlooked step in concrete construction. Proper curing maintains moisture, temperature, and time conditions necessary for the hydration process, which directly affects strength and durability. Without proper curing, concrete can crack, weaken, or degrade prematurely.

Several curing methods exist. Water curing, through sprinkling, ponding, or wet coverings, ensures continuous moisture. Membrane curing uses chemical compounds to retain water within the concrete. Steam curing accelerates strength gain in precast elements, while sheet curing employs plastic or wet burlap to prevent moisture loss. Regardless of the method, curing enhances compressive and tensile strength, reduces shrinkage, improves durability, and minimizes surface dusting.

Reinforcing Concrete for Structural Integrity

While concrete can handle compressive forces, reinforcement is necessary to manage tensile and bending stresses. Steel reinforcement bars (rebar) are the most common form, providing critical strength in beams, slabs, and columns. Wire mesh reinforces pavements and floors, while fiber reinforcement, both synthetic and steel~:- reduces cracking and improves toughness. Pre-stressing steel is used in specialized applications where compressive pre-loading is required.

Proper placement is essential. Reinforcement must maintain adequate cover to prevent corrosion, adhere to spacing and alignment specifications, and avoid on-site modifications without engineering approval. Attention to anchorage, lap lengths, and proper compaction ensures structural performance and longevity.

Common Challenges in Concrete Construction

Even with careful design, concrete can encounter issues. Cracking often results from shrinkage, thermal stress, or poor curing and can be mitigated with control joints and reinforcement. Segregation and honeycombing arise from improper placement or inadequate vibration, while surface defects like scaling can occur due to freeze-thaw cycles or improper finishing. Discoloration may result from inconsistent materials or curing conditions. Understanding and addressing these challenges proactively is essential for high-quality construction.

Embracing Sustainable Concrete Practices

Sustainability is a growing focus in the concrete industry. Using supplementary cementitious materials like fly ash, slag, or silica fume reduces reliance on traditional cement, lowering carbon emissions. Recycled aggregates decrease environmental impact and conserve natural resources. Emerging carbon capture technologies and optimized mix designs further enhance sustainability, enabling durable concrete with a smaller ecological footprint. Modern construction increasingly integrates these practices, balancing performance, cost, and environmental responsibility.

Innovations Shaping the Future of Concrete

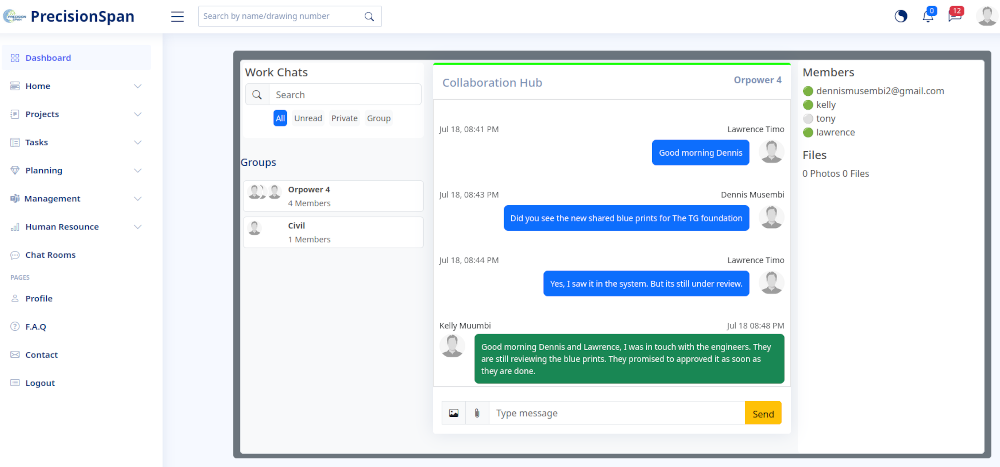

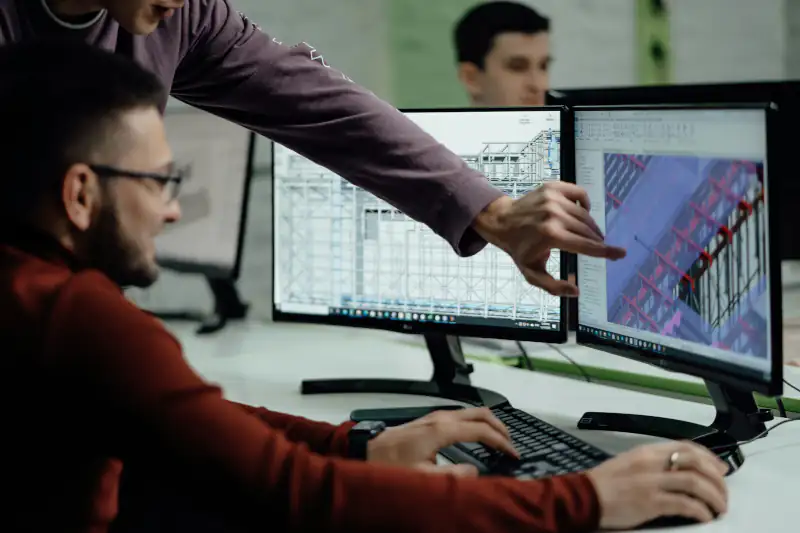

The concrete industry is embracing cutting-edge innovations. 3D-printed concrete enables rapid construction of complex structures with minimal labor. Self-healing concrete incorporates bacteria or chemical agents that seal cracks automatically, extending lifespan. Ultra-high-performance concrete (UHPC) offers exceptional strength, durability, and versatility. Digital construction management platforms, such as PrecisionSpan, complement these advances by tracking mix batches, curing schedules, and documentation, ensuring quality control and streamlined workflows.

Conclusion: Mastering Concrete for Long-Lasting Construction

Concrete is far more than a mixture of cement, water, and aggregates; it is the cornerstone of durable and sustainable construction. Mastery over its types, mix designs, curing, reinforcement, and sustainable practices allows construction professionals to build efficiently, safely, and resiliently. By integrating modern innovations and digital management systems like PrecisionSpan, companies can optimize material usage, prevent failures, and achieve superior results in every project.

Concrete remains the unsung hero of construction a material whose potential is realized only through knowledge, precision, and innovation.

0 Comments