How AI, IoT, and Robotics Are Transforming Construction in 2025

In 2025, the construction industry is undergoing a digital renaissance, driven by rapid advancements in Artificial Intelligence (AI), the Internet of Things (IoT), and robotics. These cutting-edge technologies are no longer experimental, they’re reshaping how construction sites operate, enhancing safety, improving efficiency, and dramatically reducing costs. From drone site monitoring to robotic bricklaying and smart wearables, construction is moving from blueprint to jobsite with precision and intelligence.

Today, AI in construction is being used for predictive scheduling and cost forecasting. Construction robotics are performing labor-intensive tasks like bricklaying, welding, and material handling. Meanwhile, construction of IoT through sensors and wearable devices is monitoring everything from equipment usage to worker safety. These advancements are not only modernizing construction methods but also enabling smarter decision-making and faster project delivery.

In this blog, we’ll explore how AI, IoT, and robotics are driving innovation in the construction industry and how platforms like PrecisionSpan are helping teams leverage these tools for maximum project success.

AI & Machine Learning in Construction Project Management

Artificial Intelligence is transforming project planning, execution, and oversight. AI algorithms are now capable of analyzing thousands of data points from past projects to forecast risks, optimize scheduling, and even identify potential delays before they happen. Predictive scheduling tools use machine learning to recommend the best path forward based on weather patterns, workforce availability, and material delivery timelines.

AI is also powering smarter cost forecasting. Instead of relying solely on historical spreadsheets, AI models can assess real-time cost data and adjust budgets accordingly. This helps project managers make proactive decisions that avoid costly overruns.

Furthermore, AI is improving design efficiency. Generative design tools use machine learning to explore thousands of layout alternatives that meet performance and budgetary constraints. AI can suggest design solutions that balance aesthetics, structural integrity, and energy performance in ways that manual methods cannot.

AI is also being applied to construction safety through video analytics and computer vision systems. These technologies detect unsafe behavior or potential hazards on job sites and trigger immediate alerts. Over time, they help build a safety-first culture through behavior analysis and predictive training modules.

Another application of AI is in document control and contract management. Natural Language Processing (NLP) can scan contracts, identify risks, flag inconsistencies, and help teams manage compliance. This is particularly important in large-scale infrastructure projects with dozens of stakeholders and subcontractors.

In the United States, the use of AI in construction is expected to grow at a compound annual growth rate (CAGR) of over 35% through 2030, according to a report by Grand View Research. This reflects the industry’s accelerating trust in data-driven decisions.

PrecisionSpan integrates these AI capabilities to offer dynamic project dashboards that highlight risk zones, suggest mitigations, and optimize labor allocation in real time. This makes planning and coordination not just reactive, but predictive.

Drones and Robotics on the Jobsite

Construction robotics are becoming increasingly common on modern job sites. From 3D concrete printing robots to bricklaying machines like Hadrian X, robotics are tackling repetitive, time-consuming tasks with unmatched speed and precision.

Hadrian X, for instance, can lay up to 1,000 bricks per hour, drastically outperforming human masons and reducing human error. It uses real-time data to adjust its movements for environmental conditions and blueprint precision.

Drones, on the other hand, are being used for site surveying, 3D mapping, and progress tracking. With high-resolution cameras and LiDAR sensors, drones provide project managers with real-time visuals and volumetric data. This allows teams to compare as-built conditions against BIM models, identify deviations, and track progress accurately.

Aerial drones also enhance safety inspections by scanning hard-to-reach areas and detecting structural weaknesses without placing workers in harm’s way. On larger infrastructure projects, swarm drones are being tested to carry out synchronized inspections and data collection across vast areas.

Robotics is not limited to physical labor. AI-powered robotic arms and machines are automating complex tasks like welding, steel reinforcement placement, and tunnel boring. Autonomous bulldozers and excavators, such as those developed by Built Robotics, are capable of trenching, grading, and site clearing without human operators.

Meanwhile, robotic exoskeletons are becoming a game-changer for manual workers. These wearable machines support the spine and limbs, enabling the lifting of heavier objects and reducing fatigue. The construction arm of Hyundai has already begun pilot projects using exosuits to support road and building work.

These technologies are particularly vital in regions experiencing labor shortages or increasing health and safety regulations. The U.K., for example, has allocated government funding to incentivize robotics adoption on public infrastructure projects to meet efficiency and safety mandates.

Using robotics not only accelerates construction but also enhances safety by minimizing human exposure to hazardous environments. It reduces the dependency on manual labor, which is especially critical in regions facing skilled labor shortages.

Construction IoT and Wearables

The Internet of Things is revolutionizing construction site visibility. IoT sensors embedded in equipment can monitor engine performance, fuel usage, and maintenance schedules, reducing downtime and operational costs.

Wearables such as smart helmets, vests, and boots are collecting biometric and positional data from workers. This information is analyzed to ensure compliance with safety protocols, detect fatigue, and respond quickly to accidents.

In one case study, a leading U.S. general contractor reduced jobsite accidents by 30% after equipping 200 workers with IoT-enabled helmets and vests that provided real-time feedback and fall detection alerts.

IoT in construction also supports geo-fencing, allowing managers to restrict or monitor movement in hazardous zones. Through connected systems, everything on-site becomes measurable and manageable.

Another key area is environmental monitoring. IoT devices track temperature, humidity, dust, and air quality to ensure compliance with health and safety standards. These insights help create healthier, more productive job sites.

Wearables are also helping to streamline communications. Smart helmets with built-in augmented reality (AR) displays allow workers to see project plans overlaid on the physical environment, reducing errors and improving execution. Some vests include panic buttons or fall-detection technology that alerts managers instantly.

IoT platforms also allow integration with Building Automation Systems (BAS), allowing project managers to link the construction phase directly with the operation phase for a seamless transition.

PrecisionSpan supports IoT integration by centralizing this data on a live dashboard. Managers can see equipment health, worker locations, and safety alerts in one place, enabling quick action. This centralization streamlines decision-making and reduces response time during emergencies.

Digital Twins and BIM Integration

Digital twins, virtual replicas of physical assets are gaining momentum in 2025. Built using BIM and real-time data, digital twins allow project teams to simulate construction sequences, monitor asset performance, and make data-driven decisions throughout the asset’s lifecycle.

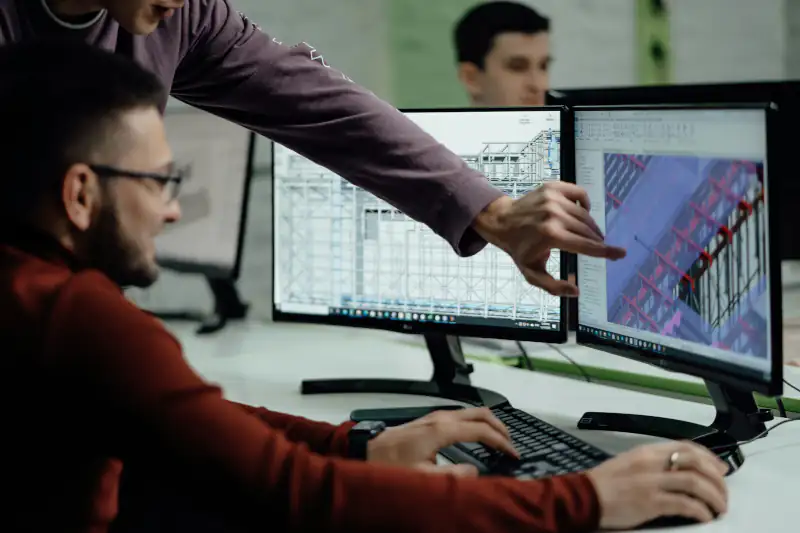

Integrating BIM (Building Information Modeling) with IoT and AI transforms the way buildings are designed and managed. Stakeholders can visualize project status, track material consumption, and plan maintenance activities with pinpoint accuracy.

Digital twins can simulate 'what-if' scenarios to optimize energy usage, space management, and facility operations. For example, a digital twin of a hospital can test emergency protocols, space reconfigurations, and HVAC efficiency without disrupting actual operations.

In addition to new projects, digital twins are being used for retrofitting and renovation. They provide insights into existing structural conditions, enabling efficient refurbishment and reuse of materials. Cities like Singapore are pioneering full-scale digital twin initiatives to manage municipal planning and infrastructure.

The power of BIM lies in its layered detail and collaborative potential. Project owners, architects, engineers, and contractors can all work off a single source of truth. Design clashes are resolved before they happen in the field. This reduces change orders and saves millions in rework.

PrecisionSpan complements digital twin technology by syncing task timelines, cost data, and resource allocation with live BIM models, providing a holistic view of the project. It bridges the gap between design intent and field execution, ensuring model-driven success.

Modular Construction and 3D Printing

Modular construction, where building components are prefabricated off-site and assembled on-site is gaining popularity due to its speed and sustainability. In tandem, 3D printing technologies are being used to fabricate complex building elements directly from digital designs.

These methods reduce waste, enhance quality control, and significantly shorten construction timelines. Combined with robotics and AI-driven quality checks, modular construction represents a shift toward a manufacturing-style approach to building.

Off-site factories are using robotic arms and AI vision systems to assemble wall panels, electrical systems, and even entire bathrooms with consistent quality. Once complete, these modules are transported to the job site for final assembly.

In 2025, 3D printing is not just used for components, it's being applied to entire housing units, especially in remote areas or disaster zones. Using specially formulated concrete, large 3D printers can erect walls and foundations in under 24 hours, at a fraction of the cost of traditional methods.

Projects such as ICON’s 3D-printed homes in Texas and housing efforts in Kenya have proven that this technology is scalable, affordable, and sustainable.

For project managers, platforms like PrecisionSpan ensure that prefabricated elements arrive on schedule and are tracked through every phase of installation, linking procurement and logistics with site execution. The software also supports Just-In-Time (JIT) delivery strategies, minimizing on-site storage and maximizing efficiency.

Benefits and ROI of Emerging Construction Technologies

The adoption of AI, IoT, and robotics in construction leads to measurable returns:

- Improved safety: Wearables and automation reduce human risk.

- Faster delivery: Robotics and modular methods cut project timelines.

- Cost savings: AI-driven forecasting avoids overruns.

- Data visibility: IoT and digital twins provide real-time insights.

- Sustainability: Modular construction and 3D printing minimize waste.

- Workforce optimization: Automation fills labor gaps.

- Higher quality: Digital inspections and robotics improve build accuracy.

- Competitive edge: Tech-driven firms win more bids and contracts.

In a McKinsey Global Institute report, companies that adopted digital technologies in construction saw productivity improvements of up to 50%, and cost reductions ranging from 10% to 20% on large-scale projects.

These benefits compound across large-scale projects, delivering better quality outcomes while keeping budgets and timelines on track. Early adopters are also seeing gains in stakeholder trust, project transparency, and long-term operational efficiency.

How PrecisionSpan Supports Technology-Driven Construction

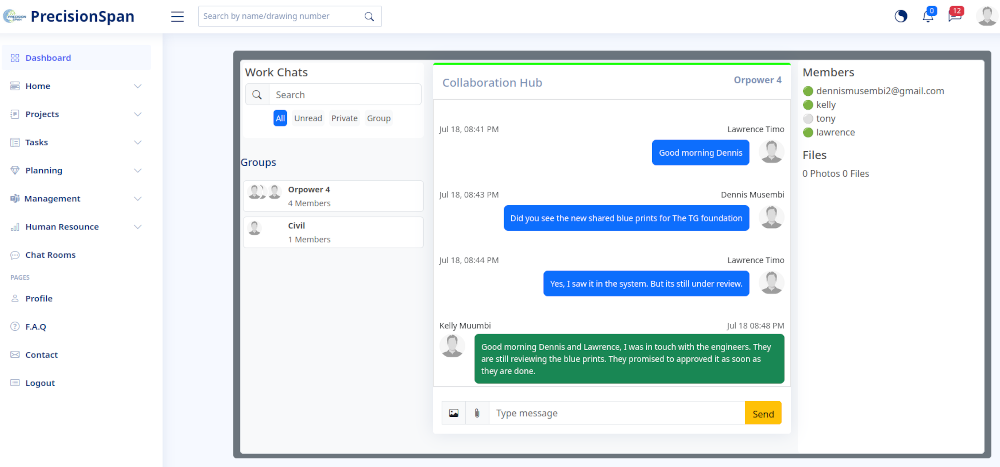

PrecisionSpan is designed to help construction firms integrate and manage advanced technologies. From AI-powered dashboards to IoT sensor integration and mobile-friendly field tools, PrecisionSpan acts as the command center for modern construction management.

- Features include:

- Real-time sync with BIM models and digital twins

- Wearable data feeds and safety alerts

- Forecasting modules powered by AI

- Integration with robotic systems and procurement schedules

- Mobile app access for field teams

- Custom workflows for modular installation tracking

- KPI dashboards and smart analytics

- Team messaging and document control

With PrecisionSpan, project managers can visualize the entire project lifecycle on a single platform. The software facilitates data-driven decision-making, proactive risk mitigation, and seamless collaboration between on-site teams and back-office stakeholders.

PrecisionSpan also includes tools for subcontractor management, change order tracking, and digital approvals, essential for maintaining accountability and transparency.

By centralizing all this data, PrecisionSpan helps teams transform insights into actions, improving coordination, reducing risk, and boosting productivity. Its intuitive interface makes it easy for on-site and office teams to collaborate using the same data source.

Conclusion

The future of construction is here and it's intelligent, connected, and automated. As AI in construction drives predictive planning, robotics handle complex tasks, and construction IoT offers real-time field data, the industry is becoming smarter, safer, and more efficient.

Firms that adopt these innovations early are gaining a competitive edge through faster builds, reduced waste, and superior quality. PrecisionSpan stands at the intersection of all these technologies, offering a platform where data, decisions, and delivery come together seamlessly.

Whether you're managing a high-rise project, an industrial facility, or a modular housing development, adopting AI, IoT, and robotics will be critical to staying ahead in 2025 and beyond. Future-forward construction firms that embrace digital transformation now are positioning themselves to lead the next decade.

Ready to embrace the future of construction?

Book a Demo or Get Started Free and see how PrecisionSpan connects your team to the tools that are shaping construction in 2025 and beyond.

0 Comments